Call08045475278

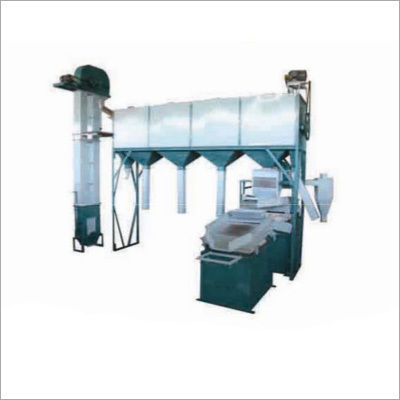

Mustard Seed Cleaning Machine

Product Details:

- Type Mustard Seed Cleaning Machine

- Material Mild Steel

- Capacity 500-1000 kg/hr

- Computerized No

- Automatic Grade Automatic

- Control System PLC Controlled

- Air Compressor Power 2 HP

350000.0 INR

X

Mustard Seed Cleaning Machine Price And Quantity

- 350000.0 INR

- 250000.00 - 562000.00 INR

- 1 Unit

- Onsite Installation & Training

- Air separation and mechanical grading

- Air Suction and Sieving

- 5°C to 45°C

- Seed Cleaning and Grading

- Yes

- Powder Coated

- Industrial Green/Grey

- Vibratory or Hopper

- Fixed

- <72 dB

- 3

Mustard Seed Cleaning Machine Product Specifications

- 220 V

- 2500 x 900 x 1600 mm

- Standard

- 3 kW

- 700 kg (approx)

- Automatic

- 2 HP

- Mustard Seed Cleaning Machine

- 900 mm (approx)

- PLC Controlled

- 500-1000 kg/hr

- Mild Steel

- 150 Liters

- No

- Onsite Installation & Training

- Air separation and mechanical grading

- Air Suction and Sieving

- 5°C to 45°C

- Seed Cleaning and Grading

- Yes

- Powder Coated

- Industrial Green/Grey

- Vibratory or Hopper

- Fixed

- <72 dB

- 3

Product Description

Facilitated by technically advancedprocess, we are offering a distinguished assortment of Mustard Seed Cleaning Machine. Thisis available in 220V-240V Voltage. Our offered seedcleaning machine is manufactured by usingpremium quality components and advanced technology by our skilledprofessionals. In order to ensure quality, this seedcleaning machine isrigorously tested on different parameters. In tune with international standard,we provide MustardSeed Cleaning Machine in various models, as per theever-evolving requirement of our customers.

Advanced Seed Cleaning and Grading Technology

This machine combines both air separation and mechanical grading with precision, using three high-quality sieves. The integration of air suction efficiently removes lighter impurities, while variable mesh sizes support effective grading to meet industry standards. Its robust sensor and PLC control ensures consistent, high-capacity processing for various operational demands.

User-Friendly Operation with Professional Support

Designed for ease of use, the Mustard Seed Cleaning Machine offers automatic, PLC-controlled operation. Material can be fed using vibratory or hopper methods for convenience. Onsite installation and comprehensive training are provided, ensuring your team quickly becomes proficient in efficient operation and basic maintenance tasks.

Reliable Performance and Industrial Durability

Engineered with mild steel construction and a protective powder coating, this machine withstands industrial environments. Its low-noise operation, effective dust collection, and fixed, space-efficient design make it highly suitable for continuous use in small to medium-scale seed processing units, ensuring quality output and a safer workspace.

FAQs of Mustard Seed Cleaning Machine:

Q: How does the Mustard Seed Cleaning Machine operate?

A: The machine uses a combination of air suction and mechanical sieving for cleaning and grading seeds. Seeds are fed via a vibratory chute or hopper, then separated using three sieves and air flow to remove dust and lighter impurities. A PLC control system automates the process for consistent results.Q: What types of impurities can this machine remove from mustard seeds?

A: This machine effectively removes lighter impurities such as dust, husks, straw, and immature seeds using air suction, while the mechanical sieves segregate seeds by size for accurate grading and a cleaner end product.Q: When is it ideal to use the Mustard Seed Cleaning Machine?

A: It is best used after harvest or whenever seeds require cleaning before packaging, export, or oil extraction. The equipment works efficiently within an operating temperature range of 5C to 45C, making it suitable year-round in most Indian climates.Q: Where is the installation and training offered?

A: Onsite installation and training are provided in India. Our technicians assist at your processing facility, ensuring proper machine setup and guiding your staff through operational and basic maintenance procedures.Q: What is the process for feeding material into the machine?

A: Material is fed using either a vibratory feeder or hopper system, ensuring an even and consistent seed flow into the cleaning section. This controlled feeding supports uniform cleaning and grading without clogging or overflow.Q: How does the built-in dust collection system benefit the operation?

A: The integrated dust collection system captures airborne particles during cleaning, improving air quality in the processing area and reducing machine maintenance by preventing dust accumulation inside the equipment.Q: What are the operational benefits of using this machine?

A: Operators benefit from its automatic, PLC-based system, high throughput (5001000 kg/hr), low noise (<72 dB), and robust build. The powder-coated mild steel structure ensures longevity, while onsite training enables smooth day-to-day use with minimal downtime.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese